Submitted by Anonymous on Mon, 23/01/2023 - 11:05

Precision agriculture enables farmers to closely monitor the status of their crops (such as nutrients, pests and diseases, and water stress) in real time, and use that information to apply just the right amount of management input in the right place to ensure the plant grows optimally. Such practices help ensure resources are not wasted, and the environment and our health is better protected.

The last two decades have seen many advances in the monitoring of crop plant status and health using modern ‘remote’ technologies, especially those using satellite technologies. These provide information by monitoring different external characteristics of the crops, which scientists then correlate with the desired characteristic to determine the crops’ status.

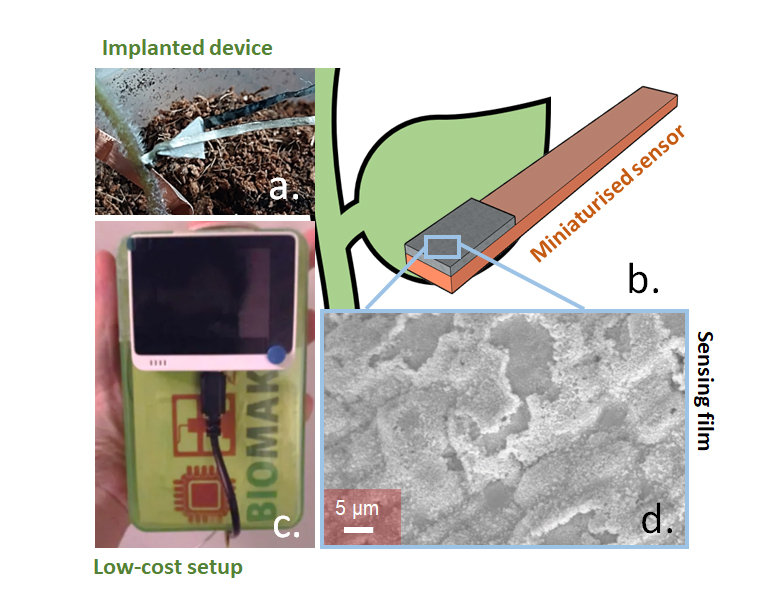

The development of sensing devices that provide direct information by being implanted inside the crops is a crucial next step for the development of these technologies, but is still in the early stages of development.

In a groundbreaking development, Professor Jim Haseloff and his team at the Engineering Biology Interdisciplinary Research Institute in the Department of Plant Sciences has developed a low-cost electrochemical sensor that can be used to monitor pH in xylem sap.

“Measuring plant biomarkers in xylem sap directly can give us a lot more information compared to traditional indirect methods, and could even help us prevent crop losses. However, this has been a very challenging and expensive thing to do up to this point, which is why we decided to focus on this area”, said study leader Dr Antonio Ruiz Gonzalez.

The group used ruthenium oxide-based nanoparticles, chosen for their biocompatibility and chemical stability and their capacity to selectively react with H+ ions, to develop sensor films 80 nm thick and roughness below 3 nm, and implanted these devices in xylem of tomato plants. The sensor provided data for ten hours in tomato plants into which it had been implanted.

‘Our initial work to develop the sensors resulted in high noise rates, rendering the devices fairly useless as we’d not be able to separate the data we were looking for from the noise.’ explained Prof Haseloff.

‘To improve their stability and reduce the noise, we incorporated a cellulose-based coating onto the electrodes and used a heating system to ensure its homogeneity. Our final system enabled us to deposit nanometrically-thin films of a range of dimensions on many different substrates, and all for less than twenty five pounds each.’

The system also incorporated another sensor that allowed the measurement of environmental parameters such as temperature, humidity and VOC concentrations that sent its data wirelessly via an online server. The team translated the codes needed to operate the device into the XOD programming tool for ease of use in practice.

Read the paper: Ruiz-Gonzalez, A., Kempson, H,. Haseloff, J. 2022. In vivo Sensing of pH in Tomato Plants Using a Low-Cost and Open-Source Device for Precision Agriculture. https://www.mdpi.com/2079-6374/12/7/447

Find out more: