Submitted by A.J. Benton on Thu, 30/11/2023 - 11:12

Predicting hidden toxins in vital food supply chains

The implications of aflatoxin, a highly toxic compound, entering food systems are far reaching for human and animal health. Produced by fungal species of the genus Aspergillus, aflatoxin contamination of staple crops such as maize is monitored and highly regulated throughout the supply chain to prevent food supplies becoming unsafe. This is particularly vital in maize grown and processed in climate vulnerable regions, where high temperatures and humidity exacerbate fungal growth.

Responding to requests from industrial processors in India, a team of modellers at the University of Cambridge have developed an integrated epidemiological model framework to predict aflatoxin contamination in maize throughout the supply chain, from field crop to storage to processing plant, addressing the serious threat posed by the fungal growth and toxin. The model provides a tool to optimise sourcing, guide farmer and supplier processes, and for testing control interventions to reduce the risk of aflatoxin contamination and income loss for both farmers and suppliers.

Serious by nature

The European Food Safety Authority data recently revealed that up to 80% of the crops grown, stored and traded are contaminated with detectable quantities of secondary fungal metabolites known as mycotoxins, with up to 20% recorded at levels beyond legal limits for contamination. Among mycotoxins, Aflatoxin B1 (AFB1) is one of the most potent human carcinogens produced by a group of fungi, Aspergillus spp. Human exposure to aflatoxins through diet and skin exposure can lead to liver cancer, immune diseases and malnutrition. Livestock raised on contaminated cereals are also at risk of liver damage, reduced growth or death and can indirectly pose a further risk to humans if used for food.

Aspergillus flavus, a common source of aflatoxin, is a widely distributed and prolific soil saprotroph that can infect a wide range of crops, including cereals, legumes and tree nuts. The wind-dispersed spores (conidia) are capable of infecting maize, one of the most widely produced cereals worldwide. Maize is crucial for food security, animal feed and is also used as a raw material in industrial processing. Because of the serious nature of aflatoxin contamination in maize traded through local and international markets, attention has focused on the development of models to predict risk of A. flavus contamination in maize-growing regions and to identify effective intervention strategies that reduce contamination in pre-harvested crops, at farm-level. However, fungal growth and toxin accumulation continue after maize is harvested, especially in low-income countries where storage conditions are limited by logistical and cost constraints.

[Figure right: Background: Mature conidiophore of Aspergillus flavus, showing (inset) the structural arrangement of the mycotoxin, Aflatoxin B1 (AFB1), a potent human carcinogen. Image: Medmyco CC-BY-SA-4.0]

The Model

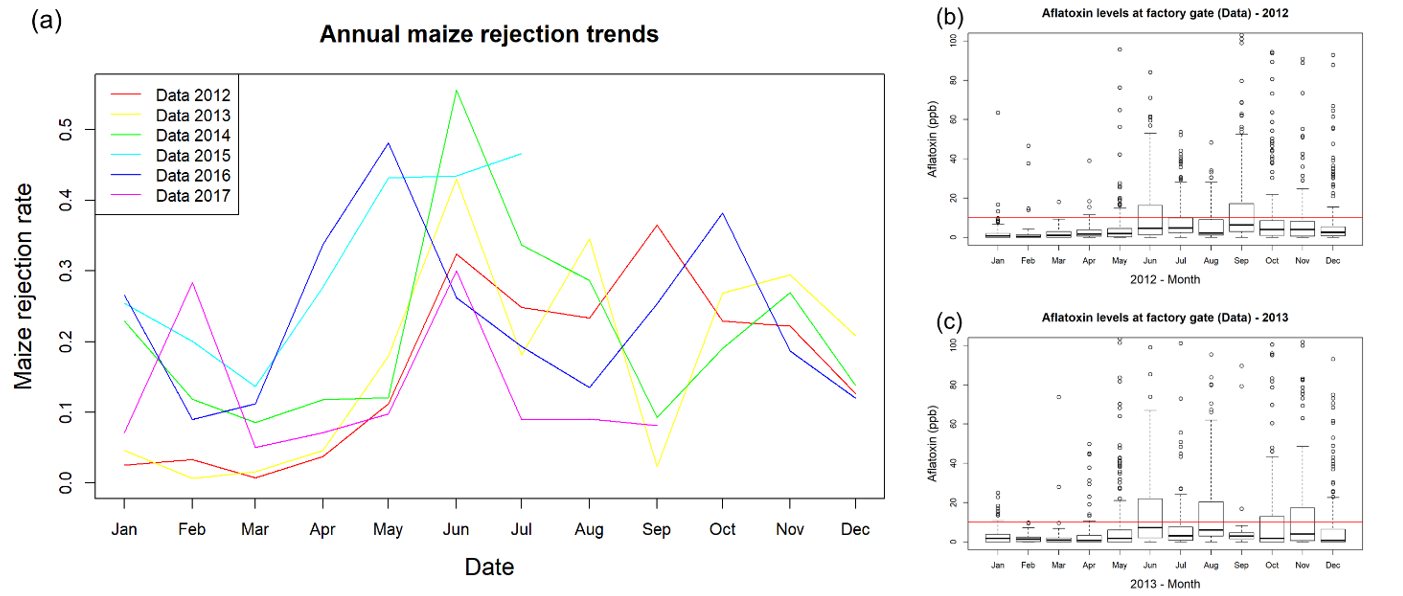

The high levels of aflatoxin contamination in maize consignments arriving at a maize-processing plant in Hyderabad, India led industrial partners to a group of researchers in the Epidemiology & Modelling Group, at the University of Cambridge with the aim of developing new methods to predict and ultimately reduce rejection of consignments arriving at factory gates, thus reducing the burden of income loss for local farmers and suppliers.

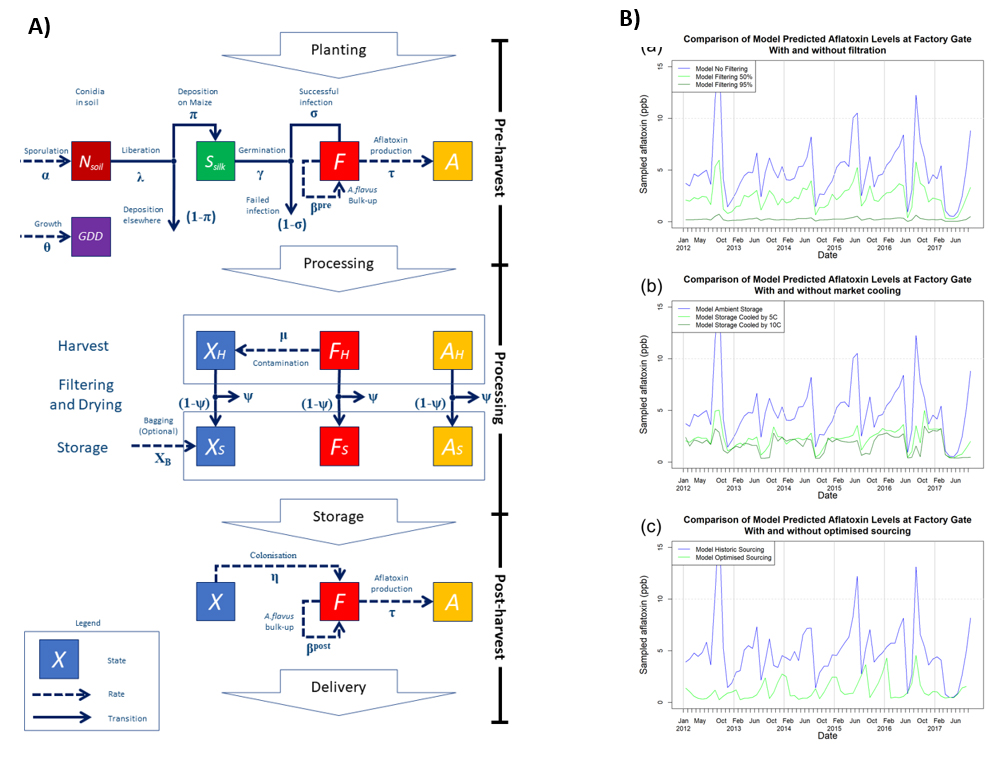

The approach was to develop an integrated, meteorology-driven, epidemiological model framework that predicts aflatoxin contamination across the entire supply chain, with a view to optimising sourcing, guiding farmer and supplier operations, and to produce a flexible framework that could be adapted for different countries. The researchers used data on the contamination levels of aflatoxin in daily shipments, received from three different sourcing regions over six years in India. Constructing a mechanistic model, and using approximate Bayesian computation to parameterise the model, they successfully replicated the overall profile, scale and variance of the historical aflatoxin datasets. The model was used to illustrate the dynamics of A. flavus growth and aflatoxin production during pre-and post-harvest phases, in different growing regions. In addition, the model can be used for control intervention scenario testing, to assist farmers and suppliers in selecting intervention strategies which may serve to reduce aflatoxin contamination and avoid consignment rejection.

[Above: A) Schematic diagram showing A. flavus growth and aflatoxin production on maize occurs during the supply chain. B) Scenario analysis - Using the model to predict the effectiveness of aflatoxin control interventions: a) aflatoxin levels at the factory gate with no intervention (blue) are compared with the predicted level with the adoption of filtering with 50% effectiveness (green) and 95% effectiveness (dark green). b) aflatoxin levels at the factory gate with no intervention (blue) are compared with the predicted with the adoption of cooled storage facilities, by 5oC below ambient temperatures (green) and 10oC below ambient temperatures (dark green). c) The observed aflatoxin levels at the factory gate using historic sourcing (blue) are compared with predicted levels if applying an optimal sourcing strategy (green).]

Increasing threats and vulnerabilities

Maize is a primary income source and an important component for nutrition in the diets of many people in countries across Sub-Saharan Africa, Latin America, and Asia. Food production in several of these regions is already under increasing pressure and is predicted to further decline under conditions brought about by climate change. This is significant because the optimal conditions for the growth of the saprotrophic fungi that produce aflatoxins are associated with increased temperature and humidity. While high-income countries are able to rely on high tech solutions for reducing levels of contamination during growing, storing and transporting cereal crops, those that are less well-resourced require reliable, cost-effective methods of reducing the risk to food supplies.

Despite the awareness of the dangers of contaminated maize entering the food supply chain, and models that can accurately predict levels of Aspergillus and aflatoxin in the field, numerous cases of aflatoxin contamination at the factory gate are commonly reported. Where most risk prediction models have focused on the pre-harvest dynamics of A. flavus growth and aflatoxin production, the Cambridge team’s integrated epidemiological modelling framework enables coverage of the entire supply chain from planting to delivery, and allows for predicting the costs and benefits of various aflatoxin mitigation interventions.

[Above: Motivating data: a) Monthly rejection rates at MARS processing facility due to sampled aflatoxin levels exceeding 10-ppb limit for 2012-2017 and monthly sampled aflatoxin distributions for 2012 (b) and 2013 (c).]

Read the paper:

Richard O.J.H. Stutt, Matthew D. Castle, Peter Markwell, Robert Baker, Christopher A. Gilligan. An integrated model for pre- and post-harvest aflatoxin contamination in maize. npj Sci Food 7, 60 (2023). https://doi.org/10.1038/s41538-023-00238-7

Written by Alison Scott-Brown and colleagues in the Epidemiology and Modelling group

[Banner image by Temmydolph, Wikimedia commons CC-BY-SA-4.0]